Systems

Flexible 19-inch industrial standard based systems

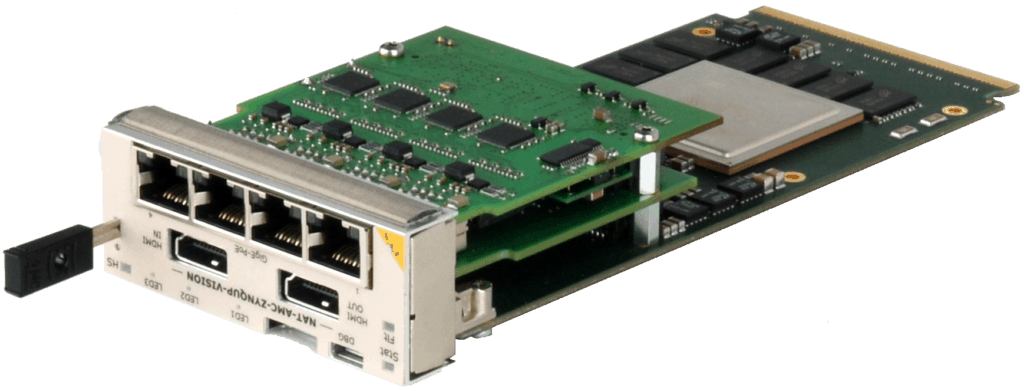

NATvision-FLEX-S (Up to 4 cameras)

The NATvision-FLEX-S is is our desktop solution indent for lab usage or for light weight vision applications with one frame grabber board and one CPU board.

The FPGA frame grabber board can be used for image processing tasks such as pre-filtering and Machine Vision inference. The x86-based CPU processing board brings opportunities for image post-processing and distribution.

Key Features:

- Two slot, 19-inch industrial standard chassis

- FPGA-based vision framegrabber board

- x86-based processor board

- Integrated management and switching

Applications:

- Applications with up to 4 cameras

- Cost sensitive applications

- Image Processing

- Machine Learning

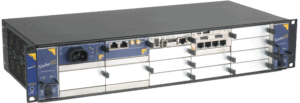

NATvision-FLEX-M (Up to 48 cameras)

NATvision-FLEX-M is our mid-size solution in 19″ format for powerful vision applications using multiple frame grabber boards, CPUs and digital I/O.

This MicroTCA system supports up to 12 framegrabber boards and is therefore ideal for applications requiring up to 48 cameras per processing node. Cameras and framegrabber boards can be synchronized using backplane trigger signals.

Key features:

- 12 slot 19-inch industrial standard chassis

- Support for up to 48 cameras

- Trigger signals and synchronization

- Redundant system management, power supply and switching

- High level availability and short service time

Applications:

- High density processing nodes

- Quality control and automation

- Image processing

- Machine Learning

NATvision-Flex-L (Up to 96 cameras)

The NATvision-FLEX-L is the solution for sophisticated vision applications requiring a huge number of cameras, CPUs, GPUs and digital I/O.

This 19″ MicroTCA system supports up to 96 cameras by using double width mid-size frame grabber boards. The support for rear-transition modules gives additional freedom and space for camera and control interfaces on the rear side of the chassis. Cameras and framegrabber boards can be synchronized using backplane trigger signals.

Key Features:

- 12 slot 19-inch industrial standard chassis

- Support for up to 96 cameras

- Trigger signals and synchronization

- Rear Transistion Modules (RTM)

- Optical Uplink (PCI express 3.0, x48) for creating cascades

- Redundant system management, power supply and switching

- High level availability and short service time

Applications:

- High density, high power processing nodes

- Quality control and automation

- Image processing

- Machine Learning

- High energy physics